RAHIM SUPER EXTREME LTD.

Rahim Steel is proud to introduce TMT 500W through its newest state of the art delicate Rahim Super Extreme Ltd. It also gives the rare opportunity of introducing 3rd generation management into the steel industry. Rahim Super Extreme Ltd. will enhance the industry practices by increasing the standard of quality of demand bars that the market is currently receiving.

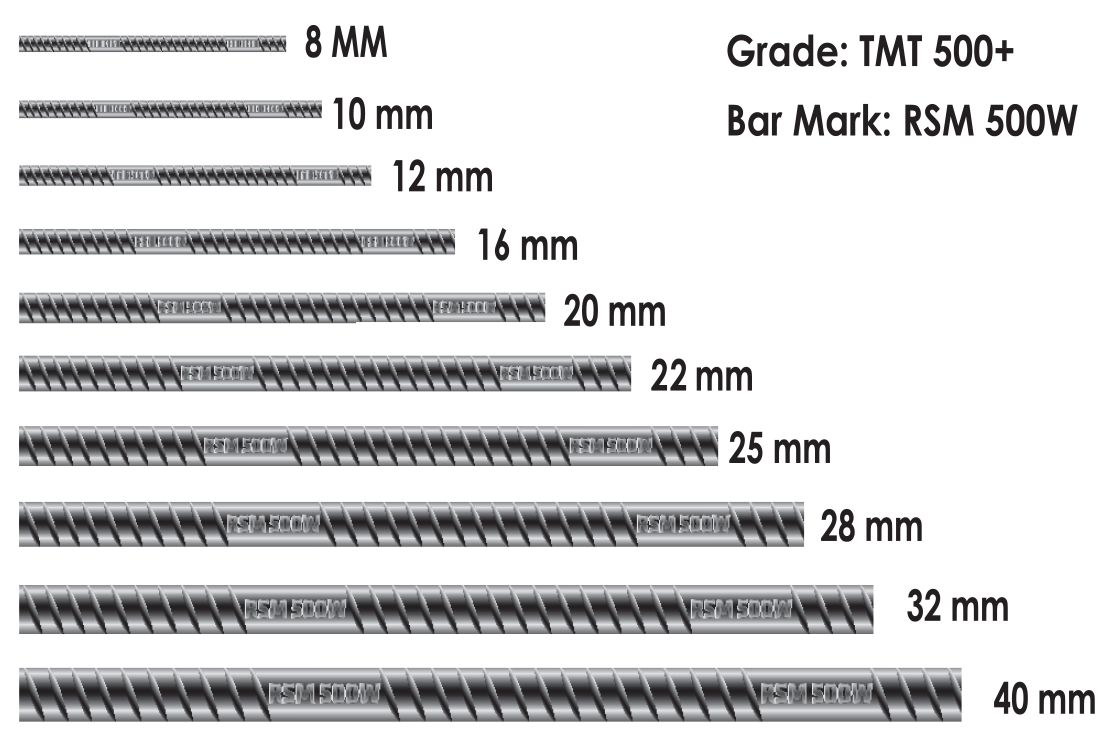

RSM 500W is manufactured using European Technology. Rahim Super Extreme Ltd. is capable of producing 500,000 MT/Y with a varied product range of 8mm to 40mm TMT Bars

Vision of Rahim Super Extreme Ltd.

To produce premium TMT 500W Bar with highest standards possible under the careful supervision of the qualified Engineer / Metallurgical. The promises of providing the right product at the right time. Be a responsible corporate citizen & enhance the quality of the employees & focus on green environment friendly production process.

Product Information

Typical Mechanical Properties

Yield Strength: 500 MPa (72,500 psi) (Minimum)

Ultimate Tensile Strength: 550 MPa (79,750 psi) (Minimum)

Elongation (5%) : TY/YS 1.25% (Minimum)

Bar Reckoner

| Dia (mm) | Area (mm²) | Kg/Meter | Meter/Ton | Feet/Ton |

|---|---|---|---|---|

| 8 | 50.27 | 0.395 | 2531.6 | 8313 |

| 10 | 78.54 | 0.617 | 1622 | 5320 |

| 12 | 113.10 | 0.888 | 1126.4 | 3694 |

| 16 | 201.06 | 1.578 | 633.6 | 2078 |

| 20 | 314.16 | 2.466 | 405.5 | 1330 |

| 22 | 380.13 | 2.984 | 335.1 | 1099 |

| 25 | 490.87 | 3.853 | 259.5 | 851.2 |

| 28 | 615.75 | 4.834 | 206.9 | 678.6 |

| 32 | 804.25 | 6.313 | 158.4 | 519.5 |

| 40 | 1256.64 | 9.865 | 101.4 | 332.5 |

Note: Above table shows the nominal masses per unit length & length per 1000 kg. Actual bars are rolled to within -3% (Maximum) of nominal mass per unit length.

Referenced Standards

Mechanical Properties

| Code | Yield Strength or 0.2% prof stress MPa (Min.) | Tensile Strength MPa (Min.) | Elongation % on 5D G.L (Min.) | Elongation at Maximum Force (Min.) | Bending Pin Dia | Re-bend Test |

|---|---|---|---|---|---|---|

| BDS – ISO 6935 | 500 | 550 | 14% | 7% | 3D – 7D | 5D – 10D |

| BS 4449 GR. B500 C | 500-650 | 15% more than Y.S. | – | 7.5% | – | 4D – 7D |

| DIN 488 BST 500 | 500 | 550 | 10% on D 10 | – | 5D – 8D | – |

Key Features of RSM 500W

Product Range

- High design yield strength of 500 MPa (72500 psi) (Min.)

- Requires 15% less steel in construction compared to grade 60 rebars available in the market.

- The bars have superior bend-ability & can be safely bent without cracking.

- All bar sizes are rolled to a very close tolerance only possible on a fully computerized rolling mill so that customers get more meters of steel per ton – more value for money without having to sacrifice structural integrity. Estimated savings: 0.5%.

- De-scaled bars have better bonding with concrete and less wastage at site. Estimated savings 0.5%.

- RSM 500 W TMT bar is safely weldable under field conditions. Another 0.5% to 1.5% of steel is saved by avoiding large splices.

- The bars are needle-straight, thanks to the QTB process – no need for straightening on the construction site.

QTB Process

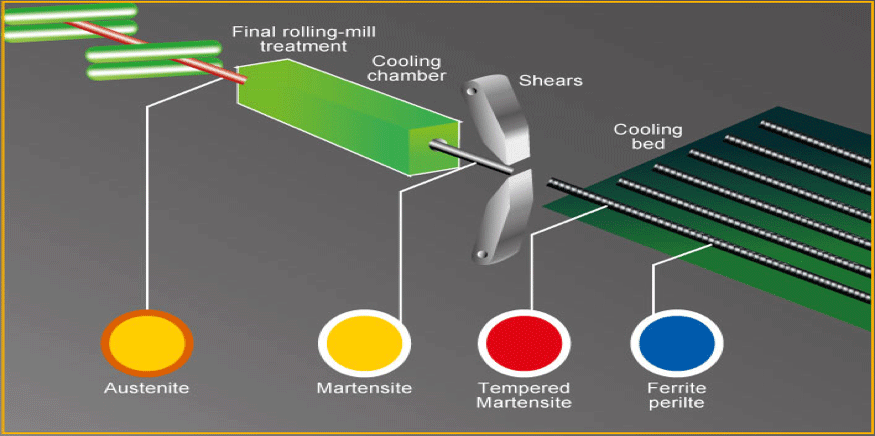

RSM 500 W rebars are hot-rolled from prime quality steel billets & subjected to on-line thermo-mechanical treatment in three successive stages.

Quenching :

The hot rolled bar leaving the final mill stand is rapidly quenched by high pressure water in special venturi tubes. This hardens the surface of the bar to a depth optimized for each section through formation of martensitic rim, while the core remains hot and austenitic.

Self Tempering :

As the bar leaves the quenching venturi tube the core remains hot compared to the surface, allowing heat to flow from the core to the surface which causes tempering of the outer martensitic layer into a structure called Tempered Martensite. The core still remains austenitic at this stage.

Atmospheric Cooling:

This takes place on the cooling bed, where the austenitic core is transformed into a ductile ferrite-pearlite structure. Thus the final structure consists of an optimum combination of strong outer layer (tempered martensite) with a ductile core (ferrite-pearlite). This gives RSM 500 W Bars a unique combination of high strength and ductility.

Rahim Super Extreme Ltd. promises to ensure stake holders & share holders the same level of commitment in excellence, in product, price, grade, quality & benefits which has been ensured by Rahim Steel since 1958.

ASTM - A615 - 90, Grade - 60

High strength deformed (HSD) Reinforcement Bars (Re-Bars) produced in our factory fully conform to (ASTM) American Society for Testing & Materials ASTM – A615 – 90, Grade – 60 & necessarily have minimum yield strength of 60,000 psi (5250 Kg/Cm²) & minimum ultimate tensile strength of 90,000 psi (6375 Kg/Cm²). We also produce re-bars conforming to ASTM – A615 – 90, Grade – 40.

HSD Re-Bars

- Natural Inherent Strength

- Highest Ultimate Strength

- Best Technical Function

- Most Economical

- Highest Yield Strength

- Highest Bond Strength

- Greatest Safety