RSM B420DWR

Mechanical Property

| Steel Grade | Standard | Frog Mark | Yield Strength (MPa) | TS/YS Ratio | Elongation% (G.L = 5D) | |

|---|---|---|---|---|---|---|

| Min | Max | Min | Min | |||

| B420DWR | BDS ISO 6935-2:2016 | RSM // Dia // B420DWR | 420 | 1.3xYS(min) | 1.25 | 16 |

Chemical Property

| Steel Grade | Standard | Frog Mark | C% (Max) | Mn% (Max) | Si% (Max) | S% (Max) | P% (Max) | CEV% (Max) |

|---|---|---|---|---|---|---|---|---|

| B420DWR | BDS ISO 6935-2:2016 | RSM // Dia // B420DWR | 0.30 | 1.50 | 0.55 | 0.040 | 0.040 | 0.56 |

TMT Process

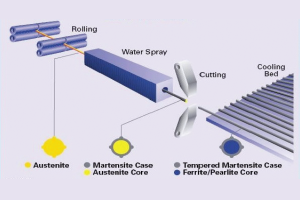

RAHIM STEEL is using the world prominent latest Enhancement Auto Feedback Temcore to develop Thermo Mechanically Treated (TMT) rebars. The deformed bars are produced in state-of-the-art plants under the close supervision of high-caliber metallurgists and engineers. RSM B420DWR rebars are hot rolled from steel billets and subjected to PLC controlled on line thermo mechanical treatment in three successive stages.

Quenching: The hot rolled bar leaving the final mill stand is rapidly quenched by high pressure water in special venturi tubes. This hardens the surface of the bar to a depth optimized for each section through formation of magnetic rim, while the core remains hot and austenitic.

Self Tempering: As the bar leaves the quenching venturi tube the core remains hot compared to the surface, allowing heat to flow from the core to the surface which causes tempering of the outer martensitic layer into a structure called Tempered Martensite. The core still remains austenitic at this stage.

Atmospheric Cooling: This takes place on the cooling bed, where the austenitic core is transformed into a ductile ferrite-pearlite structure. Thus the final structure consists of an optimum combination of strong outer layer (tempered martensite) with a ductile core (ferrite-pearlite).This gives RSM rebars a unique combination of high strength and ductility.

Application

Due to its higher uniform elongation and excellent bend ability, it could be used in all type of RCC structures as well as earthquake prone zone. It is now widely used in various goverment projects of PWD, LGED, RHD, DPHE. EED, RAJUK, WASA, City Corporations, MES etc.

For Any Solution We Are Available For You

Our Solutions

About Us

Quick Links

Follow Us

- 29/10, K. M. Das Lane Tikatuly Dhaka, Bangladesh - 1203

- 9AM - 5PM Working Hours

- +88 02 223383004

- +88 02 223383005

- +88 02 223388583

- +88 02 47113357

- +88 02 9512515